Introduction to Custom Stamped Parts of Progressive Punch Brass Stamping Retaining Parts

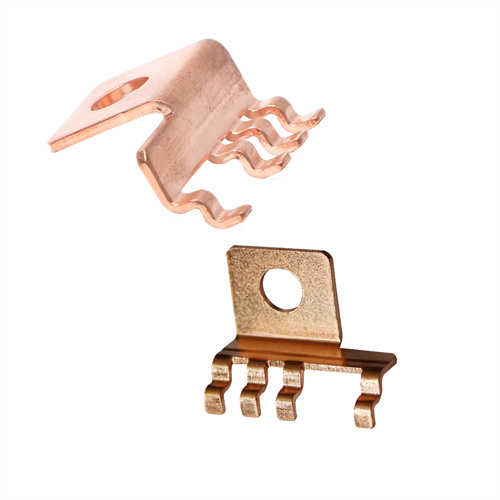

As a team deeply involved in the metal stamping industry, we understand the critical role that custom – made components play in various sectors. Custom Stamped Parts created through progressive punch brass stamping for retaining parts offer a unique combination of precision, durability, and functionality. Progressive punching is a highly efficient manufacturing technique that allows us to produce complex brass retaining parts with consistent quality, meeting the diverse needs of our clients.

Brass, with its excellent corrosion resistance, malleability, and strength, is an ideal material for retaining parts. These parts are essential in ensuring the stability and secure positioning of various components in machinery, equipment, and assemblies. Whether it’s for the automotive, electronics, or industrial equipment industries, our Custom Stamped Parts of progressive punch brass stamping retaining parts are designed to provide reliable solutions. We take pride in our expertise in this specialized area, leveraging advanced technology and a deep understanding of materials to deliver high – quality products that exceed expectations.

The Outstanding Advantages of Custom Stamped Progressive Punch Brass Stamping Retaining Parts

We are well – aware of the outstanding advantages that our Custom Stamped Progressive Punch Brass Stamping Retaining Parts bring to the market. One of the most significant benefits is the high level of efficiency offered by the progressive punching process. Unlike traditional stamping methods, progressive punching can perform multiple operations in a single pass, such as cutting, bending, and forming. This not only speeds up production but also reduces material waste, as the process is optimized to make the most of the brass sheet or coil.

Another key advantage is the precision that can be achieved. Our advanced progressive punch dies are designed with meticulous attention to detail, enabling us to produce retaining parts with extremely tight tolerances. This precision ensures a perfect fit for the components they secure, reducing the risk of 松动 or misalignment. Additionally, the use of brass as the material provides excellent corrosion resistance, making our custom – stamped retaining parts suitable for use in a wide range of environments. The combination of efficiency, precision, and durability makes our Custom Stamped Progressive Punch Brass Stamping Retaining Parts a top choice for many applications.

The Comprehensive Manufacturing Process of Custom Stamped Parts

Our manufacturing process for Custom Stamped Parts of progressive punch brass stamping retaining parts is a comprehensive and carefully orchestrated sequence of steps. It begins with in – depth consultations with our clients to fully understand their specific requirements, including the application, load – bearing capacity, and environmental conditions the retaining parts will face. Our team of experienced engineers then uses advanced CAD/CAM software to design detailed 3D models of the parts, optimizing the design for functionality, manufacturability, and cost – effectiveness.

Once the designs are finalized, we source high – quality brass materials from trusted suppliers. These materials are then fed into our state – of – the – art progressive punching presses, which are equipped with custom – made dies. During the stamping process, the brass material moves through a series of stations, each performing a specific operation to gradually form the retaining part. We closely monitor and control parameters such as pressure, speed, and die clearance to ensure consistent quality and dimensional accuracy. After stamping, the parts may undergo additional post – processing operations, such as deburring, polishing, and plating, to enhance their performance and appearance. Finally, each part is rigorously inspected to ensure it meets our strict quality standards before being delivered.

Applications of Custom Stamped Parts in the Automotive Industry

In the automotive industry, our Custom Stamped Parts of progressive punch brass stamping retaining parts are widely used and play a vital role. In engine compartments, these retaining parts are used to secure hoses, wires, and various components, preventing them from coming loose due to vibrations and movement during vehicle operation. The precision of our custom – stamped parts ensures a snug fit, reducing the risk of fluid leaks or electrical disruptions.

For the interior of vehicles, our brass retaining parts are used in the assembly of dashboard components, door panels, and seats. They provide a secure and stable connection, contributing to a quiet and comfortable driving experience. Additionally, in the exhaust system, our retaining parts help to connect pipes and ensure a proper seal, which is crucial for reducing emissions and maintaining the overall performance of the vehicle. The durability and reliability of our Custom Stamped Parts make them an essential part of automotive manufacturing.

Applications of Custom Stamped Parts in the Electronics and Industrial Equipment Sectors

In the electronics industry, our Custom Stamped Parts of progressive punch brass stamping retaining parts are essential for the assembly of various devices. In circuit boards, these parts are used to hold connectors, sockets, and other components in place, ensuring stable electrical connections. The corrosion resistance of brass protects the sensitive electronic components from environmental factors, enhancing the lifespan and reliability of the devices.

For industrial equipment, our retaining parts are used in machinery, production lines, and heavy – duty equipment. They need to withstand heavy loads, vibrations, and harsh operating conditions. The strength and durability of our custom – stamped brass retaining parts make them capable of providing secure fastening in these demanding environments. Whether it’s in a manufacturing plant, a construction site, or a mining operation, our Custom Stamped Parts ensure the smooth and reliable operation of industrial equipment.

Future Prospects of Custom Stamped Progressive Punch Brass Stamping Retaining Parts

Looking to the future, we are highly optimistic about the prospects of our Custom Stamped Progressive Punch Brass Stamping Retaining Parts. As industries continue to grow and technology advances, the demand for high – quality, reliable retaining parts will only increase. The development of new automotive technologies, the miniaturization trend in electronics, and the expansion of industrial automation will all drive the need for more precise and durable custom – stamped components.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new brass alloys, innovative progressive punching techniques, and advanced die – making technologies to further enhance the performance of our Custom Stamped Parts. By investing in state – of – the – art equipment and maintaining a focus on quality, we aim to meet the evolving needs of our clients across various industries and remain a leading provider of progressive punch brass stamping retaining parts.