Introduction to Custom Stamped Parts of Brackets & Clips

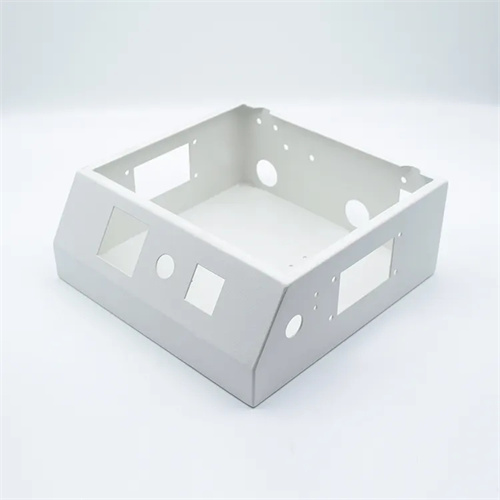

As a team deeply immersed in the industrial manufacturing sector, we understand the critical role that reliable components play in the smooth operation of industrial systems. Custom Stamped Parts of brackets and clips are essential elements that provide secure fastening, support, and organization in various industrial applications. These parts are not just simple fixtures; they are engineered solutions that can withstand the harsh conditions and heavy loads typical of industrial environments.

We take pride in our ability to offer custom – stamped brackets and clips that are tailored to the specific needs of our industrial clients. By leveraging advanced stamping techniques and a wide range of high – quality materials, we create parts that combine durability, precision, and functionality. Whether it’s for automotive assembly lines, heavy machinery, or large – scale manufacturing plants, our Custom Stamped Parts of brackets and clips are designed to be the durable solutions that industries rely on.

The Unbeatable Durability of Custom Stamped Brackets & Clips Parts

We are well – aware of the unbeatable durability that our Custom Stamped Parts of brackets and clips offer for industrial use. One of the key factors contributing to their durability is the selection of materials. We use robust metals such as steel, stainless steel, and aluminum alloys, which are known for their high strength, corrosion resistance, and ability to withstand mechanical stress. These materials are carefully chosen based on the specific requirements of each application, ensuring that the brackets and clips can endure the rigors of industrial operations.

In addition to material selection, our advanced stamping processes play a crucial role in enhancing durability. The precision stamping techniques we employ create parts with consistent quality and structural integrity. The parts are formed in a way that maximizes their strength, reducing the risk of deformation or breakage under heavy loads. Moreover, post – processing operations such as heat treatment and surface finishing further improve the durability of our Custom Stamped Parts, protecting them from wear, corrosion, and other forms of damage. This combination of quality materials and expert manufacturing ensures that our brackets and clips can provide long – lasting performance in even the most demanding industrial settings.

The Comprehensive Manufacturing Process of Custom Stamped Parts

Our manufacturing process for Custom Stamped Parts of brackets and clips is a comprehensive and highly organized sequence of steps. It starts with in – depth consultations with our clients to fully understand their industrial applications, performance requirements, and any specific design constraints. Our team of experienced engineers then uses advanced CAD/CAM software to create detailed 3D models of the parts, optimizing the design for functionality, manufacturability, and durability.

Once the designs are finalized, we source high – quality raw materials from trusted suppliers. These materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies. During the stamping process, we closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality and dimensional accuracy. After stamping, the parts undergo a series of post – processing operations. This may include deburring to remove sharp edges, heat treatment to improve mechanical properties, and surface coating to enhance corrosion resistance. Finally, each part is rigorously inspected using advanced testing equipment to ensure it meets our strict quality standards before being delivered to the client.

Applications of Custom Stamped Parts in the Automotive Industry

In the automotive industry, our Custom Stamped Parts of brackets and clips are widely used in various aspects of vehicle manufacturing. On the assembly line, they are used to hold and position components during the installation process, ensuring accurate alignment and secure fastening. For example, engine brackets made from our custom – stamped parts support the heavy engine and transmit the vibrations to the vehicle frame in a controlled manner.

These parts are also crucial for organizing and securing the complex network of wires, hoses, and pipes within the vehicle. Our custom – stamped clips provide a reliable and efficient way to route and hold these components in place, preventing them from interfering with each other and reducing the risk of damage. Additionally, in the vehicle’s body structure, brackets and clips help to reinforce the frame, enhancing the overall strength and safety of the vehicle. The durability and precision of our Custom Stamped Parts make them an essential part of the automotive manufacturing process.

Applications of Custom Stamped Parts in Heavy Machinery and Equipment

In the realm of heavy machinery and equipment, our Custom Stamped Parts of brackets and clips are indispensable. In construction equipment such as excavators, bulldozers, and cranes, these parts are used to support and connect various components. They need to withstand extreme forces, vibrations, and harsh environmental conditions, and our custom – stamped brackets and clips are designed to meet these challenges.

For industrial machinery used in manufacturing plants, our parts play a vital role in ensuring the smooth operation of the equipment. They are used to hold gears, pulleys, and other moving parts in place, preventing them from shifting or malfunctioning. The durability of our Custom Stamped Parts means that they can maintain their performance over long periods of continuous use, reducing downtime and maintenance costs for industrial operators. Whether it’s for large – scale mining equipment or specialized manufacturing machinery, our custom – stamped brackets and clips provide the reliable support and fastening solutions that industries need.

Future Prospects of Custom Stamped Brackets & Clips Parts

Looking to the future, we are highly optimistic about the prospects of our Custom Stamped Parts of brackets and clips for industrial use. As industries continue to grow and technology advances, the demand for more durable, efficient, and customized components will only increase. The development of new manufacturing techniques, such as automation and robotics, will require even more precise and reliable brackets and clips to support these advanced systems.

We are committed to continuous research and development to stay at the forefront of this evolving market. Our team will explore new materials, innovative stamping technologies, and advanced design concepts to further enhance the performance of our Custom Stamped Parts. By investing in state – of – the – art equipment and maintaining a focus on quality, we aim to meet the evolving needs of our industrial clients and remain a leading provider of durable custom – stamped brackets and clips in the global market.