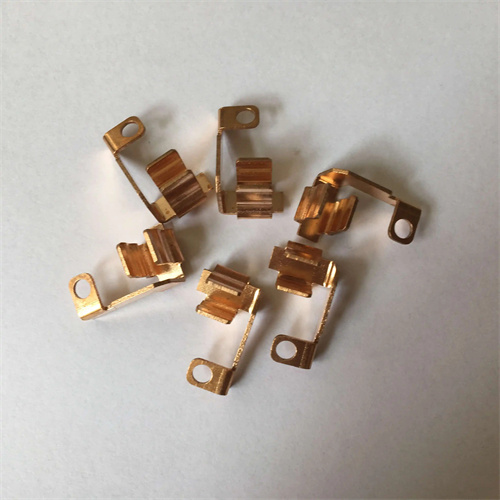

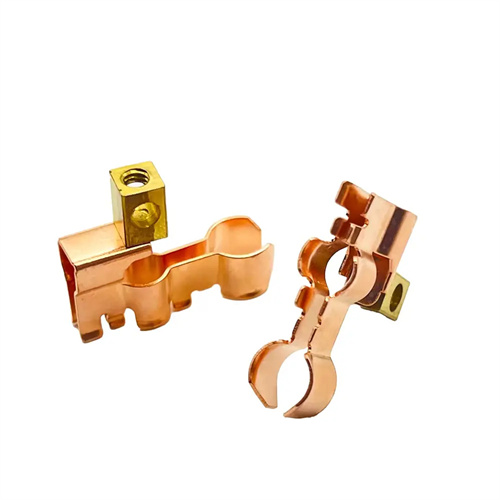

Introduction to Metal Stamping of Brass Copper Stamped Parts for Silver Electrical Connectors

As a team deeply immersed in the manufacturing of electrical components, we recognize the pivotal role that high – quality parts play in ensuring seamless electrical connections. Metal stamping of Brass Copper Stamped Parts for silver electrical connectors has become a cornerstone of our production, combining the unique properties of brass, copper, and silver to create connectors that are both reliable and efficient. Brass offers excellent corrosion resistance and mechanical strength, copper provides superior electrical conductivity, and silver, with its unparalleled conductivity and low contact resistance, enhances the overall performance of the connectors.

In today’s rapidly evolving technological landscape, where electrical devices demand higher precision and reliability, our metal – stamped components are engineered to meet the most stringent requirements. From consumer electronics to complex industrial systems, these connectors are essential for establishing secure electrical pathways. We take pride in our ability to produce Brass Copper Stamped Parts for silver electrical connectors that not only adhere to industry standards but also exceed customer expectations in terms of quality and functionality.

The Distinctive Advantages of Brass Copper Stamped Parts for Silver Electrical Connectors

We are well – aware of the numerous distinctive advantages that our Brass Copper Stamped Parts for silver electrical connectors offer. One of the key benefits is the exceptional electrical conductivity provided by the combination of copper and silver. Copper, known for its high conductivity, forms the base of the connector, while silver plating or alloying further reduces contact resistance, ensuring minimal signal loss and efficient power transfer. This is crucial in applications where high – speed data transmission and stable electrical performance are required.

The corrosion resistance of brass acts as a safeguard, protecting the internal copper and silver components from environmental factors such as moisture, oxidation, and chemical exposure. This extends the lifespan of the connectors and maintains their performance over time. Additionally, the malleability of brass and copper allows for the creation of intricate shapes through the metal – stamping process, enabling us to produce connectors that fit precisely into various electrical systems. The durability of these materials also ensures that the connectors can withstand repeated mating and unmating cycles, making them ideal for applications that require frequent connection and disconnection.

The Meticulous Metal Stamping Process of Brass Copper Stamped Parts

Our metal stamping process for Brass Copper Stamped Parts is a meticulously orchestrated sequence of steps designed to achieve the highest level of precision and quality. It begins with the design phase, where our team of experienced engineers collaborates closely with clients to understand their specific requirements. Using advanced CAD software, we create detailed 3D models of the connectors, optimizing the design for functionality, manufacturability, and cost – effectiveness. Factors such as electrical requirements, mechanical stress, and environmental conditions are carefully considered during this stage.

Once the designs are finalized, we source high – quality brass and copper sheets. These raw materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies. The stamping process involves precisely cutting, bending, and forming the metal sheets into the desired shapes. We closely monitor and control parameters such as pressure, speed, and temperature to ensure consistent quality throughout the production run. After stamping, the parts undergo a series of post – processing operations, including deburring, polishing, and the application of silver plating or alloying. Each part is then subjected to rigorous quality inspections to ensure it meets our exacting standards.

Applications of Brass Copper Stamped Parts in Silver Electrical Connectors

Our Brass Copper Stamped Parts for silver electrical connectors find extensive applications across a wide range of industries. In the consumer electronics industry, they are used in devices such as smartphones, laptops, and tablets. These connectors ensure reliable charging, data transfer, and connectivity, enhancing the user experience. The high conductivity and low contact resistance of the silver – enhanced connectors are essential for maintaining fast data transfer speeds and stable power supply in these devices.

In the automotive sector, our connectors play a crucial role in various electrical systems, including engine control units, infotainment systems, and electric vehicle charging infrastructure. The corrosion resistance and durability of the brass and copper components, combined with the superior conductivity of silver, make them suitable for withstanding the harsh conditions inside a vehicle, such as vibrations, temperature fluctuations, and exposure to moisture. Additionally, in the telecommunications industry, our silver – electrical connectors are used in network switches, routers, and fiber – optic communication systems, enabling high – speed data transmission and reliable communication.

Quality Control of Brass Copper Stamped Parts for Silver Electrical Connectors

Quality control is the cornerstone of our production of Brass Copper Stamped Parts for silver electrical connectors. We understand that even the slightest defect in these components can have a significant impact on the performance of the entire electrical system. To ensure the highest quality, we have implemented a comprehensive quality management system that covers every aspect of the manufacturing process.

All incoming brass and copper materials are thoroughly inspected for chemical composition, mechanical properties, and surface quality. During the stamping process, in – line inspections are carried out regularly to detect and correct any potential quality issues immediately. After production, each connector undergoes a series of rigorous tests, including electrical conductivity testing, tensile strength testing, and corrosion resistance testing. We also conduct visual inspections to ensure the proper application of silver plating or alloying. Any part that fails to meet our strict quality standards is rejected, and the root cause of the defect is investigated and addressed to prevent recurrence.

Future Prospects of Brass Copper Stamped Parts for Silver Electrical Connectors

Looking to the future, we are highly optimistic about the prospects of our Brass Copper Stamped Parts for silver electrical connectors. As technology continues to advance, with the increasing adoption of 5G, the Internet of Things (IoT), and artificial intelligence, the demand for high – performance electrical connectors will only grow. These emerging technologies require connectors that can handle higher data transfer speeds, lower power consumption, and more reliable connections.

We are committed to continuous research and development to stay at the forefront of this evolving industry. Our team will explore new materials, manufacturing techniques, and design improvements to further enhance the performance of our connectors. For example, we are researching advanced silver – based alloys and plating methods to further reduce contact resistance and improve durability. By investing in innovation and maintaining our focus on quality, we aim to meet the evolving needs of our customers and ensure that our Brass Copper Stamped Parts for silver electrical connectors remain a leading choice in the market.