Introduction to Medical-Grade Brass Copper Stamped Parts

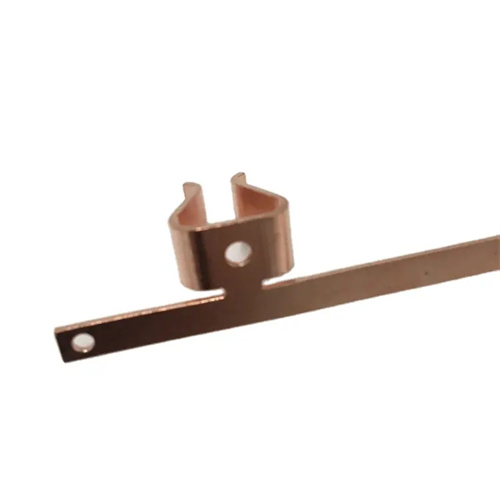

As a team deeply engaged in the manufacturing of critical components for the medical industry, we recognize the indispensable role that high – quality parts play in surgical equipment. Medical – Grade Brass Copper Stamped Parts have emerged as essential elements, providing the reliability, precision, and safety required in the demanding environment of surgical procedures. Copper, with its inherent antibacterial properties, excellent thermal and electrical conductivity, and malleability, is the ideal material for crafting parts that can withstand the rigors of medical applications.

In the field of surgery, where even the slightest flaw in equipment can have serious consequences, the use of medical – grade parts is non – negotiable. Our Brass Copper Stamped Parts are specifically engineered to meet the stringent standards of the medical industry, ensuring that surgical equipment functions flawlessly and safely. From the smallest connectors to complex structural components, each part we produce is a testament to our commitment to quality and precision in medical manufacturing.

The Unique Advantages of Medical-Grade Brass Copper Stamped Parts

We take great pride in the numerous unique advantages that our Medical – Grade Brass Copper Stamped Parts offer for surgical equipment. One of the most significant benefits is copper’s natural antibacterial properties. In a surgical setting, where preventing the spread of infections is of utmost importance, these parts can help reduce the risk of contamination. Copper ions have been proven to inhibit the growth of bacteria, fungi, and viruses, making our stamped parts a valuable asset in maintaining a sterile environment.

In addition, the excellent thermal and electrical conductivity of copper is crucial in surgical equipment. For devices that require precise temperature control or reliable electrical connections, our parts ensure optimal performance. The malleability of copper also allows for the creation of complex shapes through the stamping process, enabling us to produce parts that fit seamlessly into the intricate designs of surgical instruments. Moreover, the durability of brass and copper ensures that these parts can withstand repeated sterilization processes, which is essential for maintaining the longevity and functionality of surgical equipment.

The Rigorous Manufacturing Process of Brass Copper Stamped Parts

Our manufacturing process for Medical – Grade Brass Copper Stamped Parts is a highly meticulous and regulated sequence of steps. It commences with an in – depth understanding of the specific requirements of surgical equipment. Our team of experienced engineers collaborates closely with medical professionals and designers to create detailed specifications for each part. Using advanced CAD software, we then develop precise 3D models, taking into account factors such as biocompatibility, mechanical strength, and ease of sterilization.

Once the designs are finalized, we source medical – grade copper and brass materials that meet strict quality and purity standards. These raw materials are then fed into our state – of – the – art stamping presses, which are equipped with custom – made dies. During the stamping process, we maintain strict control over parameters such as pressure, speed, and temperature to ensure consistent quality and precision. After stamping, the parts undergo a series of post – processing operations, including surface finishing, deburring, and cleaning, to remove any potential contaminants. Each part is then subjected to rigorous quality inspections and testing to ensure compliance with medical industry regulations and standards.

Applications of Medical-Grade Brass Copper Stamped Parts in Surgical Instruments

In the realm of surgical instruments, our Medical – Grade Brass Copper Stamped Parts are used in a wide variety of applications. In scalpels and forceps, these parts are used to create handles and joints that provide a comfortable grip and precise control for surgeons. The durability and strength of brass and copper ensure that these instruments can withstand the repeated stresses of use during surgeries.

For endoscopic equipment, our stamped parts are essential for creating connectors and housings. The excellent electrical conductivity of copper ensures reliable signal transmission, while the antibacterial properties help maintain a sterile environment within the endoscope. In addition, in surgical lasers and other high – tech equipment, our parts are used for components that require precise thermal management, thanks to copper’s superior heat – conducting capabilities. These applications showcase the versatility and importance of our Medical – Grade Brass Copper Stamped Parts in enhancing the performance and safety of surgical instruments.

Quality Assurance in Medical-Grade Brass Copper Stamping

Quality assurance is the cornerstone of our production of Medical – Grade Brass Copper Stamped Parts. We understand that in the medical industry, even the smallest defect can have serious implications for patient safety. Therefore, we have implemented a comprehensive quality management system that adheres to international medical standards such as ISO 13485.

All incoming materials are subjected to extensive testing, including chemical analysis, mechanical property testing, and biocompatibility assessment. During the manufacturing process, in – line inspections are carried out at every stage to detect and correct any potential quality issues immediately. After production, each part undergoes a series of final tests, including dimensional inspection, functional testing, and sterilization compatibility testing. We also maintain detailed records of the entire manufacturing process, ensuring full traceability of each part. This rigorous quality assurance process guarantees that our Medical – Grade Brass Copper Stamped Parts meet the highest standards of safety and reliability.

Future Prospects of Medical-Grade Brass Copper Stamped Parts

Looking to the future, we are highly optimistic about the prospects of our Medical – Grade Brass Copper Stamped Parts. As the medical industry continues to advance with the development of minimally invasive surgeries, robotic – assisted procedures, and other innovative techniques, the demand for high – quality, specialized surgical equipment will only increase. This, in turn, will drive the need for more advanced and reliable components like our brass and copper stamped parts.

We are committed to continuous research and development to stay at the forefront of this evolving field. Our team will explore new manufacturing techniques, material enhancements, and design improvements to further optimize the performance of our parts. By collaborating closely with medical researchers and equipment manufacturers, we aim to develop solutions that not only meet but exceed the future needs of the medical industry, ensuring that our Medical – Grade Brass Copper Stamped Parts remain a trusted choice for surgical equipment manufacturing.