Introduction to High-Volume Brass Copper Stamping Services

As a team dedicated to providing top – notch manufacturing solutions, we are proud to offer our High – Volume Brass Copper Stamping Services. In today’s fast – paced business environment, industries across the board require a reliable source for high – quality brass stamped parts in large quantities. Brass, with its remarkable properties such as excellent corrosion resistance, durability, and malleability, is an ideal material for a wide range of applications. Our high – volume stamping services are designed to meet the demands of clients who need a consistent supply of precision – made Brass Copper Stamped Parts, whether for automotive, electronics, or industrial projects.

We understand that time is of the essence in modern manufacturing. That’s why our services not only focus on producing large quantities of parts but also ensure a fast turnaround time. Coupled with our competitive pricing, we aim to provide our clients with a cost – effective and efficient solution for their brass stamping needs. From the initial consultation to the final delivery, we are committed to delivering exceptional value at every stage.

The Key Advantages of High-Volume Brass Copper Stamping Services

We take great pride in the numerous advantages that our High – Volume Brass Copper Stamping Services offer. One of the most significant benefits is the economies of scale. By producing brass stamped parts in large quantities, we can optimize our production processes, reduce material waste, and lower the per – unit cost. This cost – saving is then passed on to our clients, allowing them to enjoy competitive pricing without compromising on quality.

Our fast turnaround time is another major advantage. We have streamlined our operations, from design and prototyping to mass production, to ensure that we can meet even the tightest deadlines. Our state – of – the – art manufacturing facilities are equipped with advanced stamping presses and automated systems that can handle high – volume orders with precision and speed. Additionally, our experienced team of engineers and technicians closely monitors each production run to ensure consistent quality, making our High – Volume Brass Copper Stamping Services a reliable choice for clients with urgent or ongoing projects.

The Streamlined Production Process of Brass Copper Stamped Parts

Our production process for High – Volume Brass Copper Stamped Parts is a well – oiled machine, designed for efficiency and precision. It starts with the design phase, where our team of experts works closely with clients to understand their specific requirements. Using advanced CAD software, we create detailed 3D models of the parts, optimizing the design for manufacturability and performance. Once the design is approved, we move on to the prototyping stage, where we produce a small batch of parts to test for functionality and quality.

After prototyping, we ramp up production for high – volume orders. High – quality brass sheets are fed into our high – capacity stamping presses, which are fitted with custom – made dies. These presses can perform multiple stamping operations in quick succession, forming the brass into the desired shapes with high precision. Throughout the production process, we implement strict quality control measures, regularly inspecting the parts for dimensional accuracy, surface finish, and structural integrity. After stamping, the parts may undergo additional processes such as plating, deburring, and assembly to meet the final product specifications.

Quality Control in High-Volume Brass Copper Stamping Services

Quality control is the cornerstone of our High – Volume Brass Copper Stamping Services. We believe that maintaining high – quality standards is essential, even when producing parts in large quantities. To achieve this, we have implemented a comprehensive quality management system that covers every aspect of the production process.

All incoming brass materials are thoroughly inspected for chemical composition, mechanical properties, and surface quality. During the stamping process, in – line inspections are carried out at regular intervals using advanced measuring tools and techniques. We also conduct random sampling and destructive testing on a regular basis to ensure that the parts meet our strict quality criteria. Any defective parts are immediately identified and removed from the production line, and the root cause of the defect is investigated to prevent recurrence. Our commitment to quality ensures that our clients receive consistent, reliable Brass Copper Stamped Parts with every order.

Applications of High-Volume Brass Copper Stamped Parts

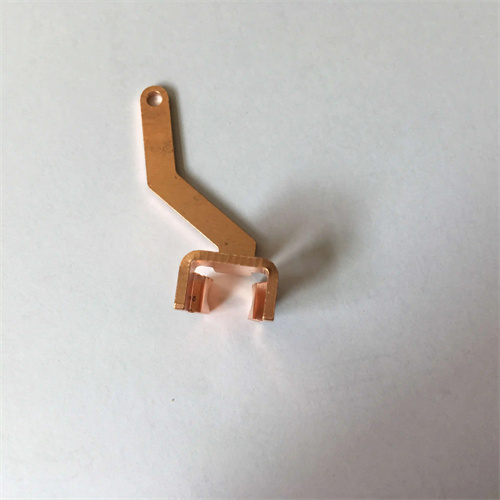

Our High – Volume Brass Copper Stamped Parts find extensive applications across various industries. In the automotive sector, they are used in components such as connectors, terminals, and brackets. The durability and corrosion resistance of brass make these parts suitable for withstanding the harsh conditions inside a vehicle, including vibrations, temperature fluctuations, and exposure to different chemicals.

In the electronics industry, our brass stamped parts are utilized in connectors, switches, and heat sinks. The excellent electrical conductivity and thermal properties of brass contribute to the efficient operation of electronic devices. Additionally, in the industrial sector, our high – volume parts are used in machinery components, plumbing fixtures, and architectural hardware. No matter the industry, our High – Volume Brass Copper Stamping Services can provide the right parts in the quantities needed to keep production lines running smoothly.

Why Choose Our High-Volume Brass Stamping Services

When it comes to high – volume brass stamping, our services stand out for our fast turnaround and competitive pricing. We understand that in today’s competitive market, businesses need to get their products to market quickly and at a reasonable cost. Our efficient production processes, combined with our large – scale manufacturing capabilities, enable us to offer a rapid turnaround on high – volume orders without sacrificing quality.

Our competitive pricing is a result of our optimized production methods, strategic sourcing of materials, and the ability to spread costs over a large number of parts. We also offer flexible pricing options to meet the specific needs of our clients, whether they require a one – time large – volume order or ongoing production. With our High – Volume Brass Stamping Services, you can expect high – quality Brass Copper Stamped Parts, fast delivery, and prices that fit your budget. Contact us today to discuss your project requirements and experience the difference for yourself.