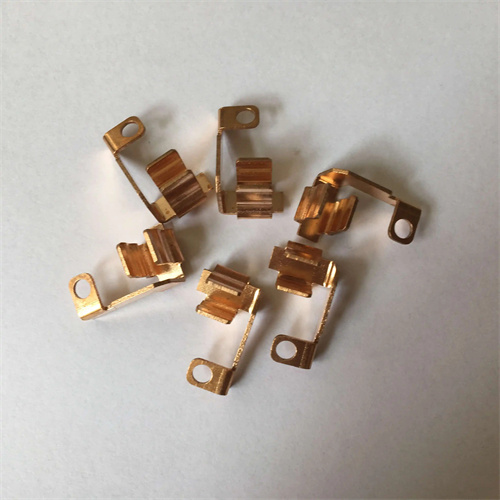

Introduction to Brass Copper Stamped Parts for Battery Button Contact

As a team deeply involved in the manufacturing industry, we understand the critical role that precision components play in various electronic devices. Among these, Brass Copper Stamped Parts for battery button contact parts stand out as essential elements. These parts are meticulously crafted to ensure seamless electrical connectivity within battery-powered devices, from small consumer electronics like watches and calculators to more complex medical devices.

Brass and copper, renowned for their excellent electrical conductivity and durability, are the primary materials used. Brass, an alloy of copper and zinc, offers a balance of strength and malleability, while copper’s high conductivity makes it ideal for electrical contacts. Together, they form stamped parts that can withstand the rigors of repeated use and varying environmental conditions. Our production process starts with selecting the highest quality raw materials, ensuring that every battery button contact part meets the stringent standards required for optimal performance.

The Advantages of Brass Copper Stamped Battery Button Contact Parts

We take pride in the numerous advantages that our Brass Copper Stamped Battery Button Contact Parts bring to the table. Firstly, their superior electrical conductivity ensures minimal resistance, which is crucial for maintaining a stable power supply in battery-operated devices. This not only enhances the overall performance of the device but also extends the battery life.

Secondly, the durability of brass and copper means that these parts can endure constant contact with battery terminals without wearing out quickly. They resist corrosion and oxidation, even in humid or corrosive environments, ensuring long – term reliability. Additionally, the stamping process allows for high – precision manufacturing, enabling us to create parts with intricate designs that fit perfectly into various device models. These advantages make our parts a preferred choice for manufacturers looking for cost – effective yet high – quality solutions for their battery contact needs.

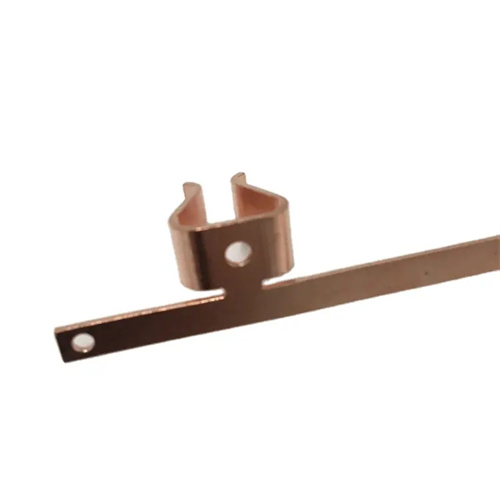

The Manufacturing Process of Brass Copper Stamped Parts

Our manufacturing process for Brass Copper Stamped Parts is a carefully orchestrated series of steps designed to achieve the highest level of precision and quality. It begins with the design phase, where our engineers use advanced CAD software to create detailed models of the battery button contact parts. These designs are optimized for functionality, manufacturability, and cost – effectiveness.

Next, the selected brass and copper sheets are fed into high – precision stamping presses. These presses use custom – made dies to cut, shape, and form the metal sheets into the desired part geometry. During the stamping process, we closely monitor parameters such as pressure, speed, and temperature to ensure consistent quality. After stamping, the parts undergo a series of finishing operations, including deburring, plating, and cleaning, to enhance their performance and appearance. Each step is carefully quality – checked to ensure that only the best parts move on to the next stage.

Applications of Brass Copper Stamped Battery Button Contact Parts

The versatility of our Brass Copper Stamped Battery Button Contact Parts makes them applicable in a wide range of industries. In the consumer electronics sector, they are commonly used in products such as remote controls, wireless earbuds, and portable gaming devices. Their reliable electrical connection ensures that these devices function smoothly, providing users with a seamless experience.

In the medical field, where precision and reliability are of utmost importance, our parts are used in devices like glucose monitors, hearing aids, and small implantable medical devices. The ability of brass and copper to resist corrosion and maintain stable electrical performance is crucial for the long – term operation of these life – saving and life – enhancing devices. Additionally, in the automotive industry, they are used in key fobs and other battery – powered automotive accessories, contributing to the overall functionality and reliability of the vehicle’s electrical systems.

Quality Control of Brass Copper Stamped Parts

Quality control is at the heart of our production of Brass Copper Stamped Parts for battery button contact. We have implemented a comprehensive quality management system that covers every aspect of the manufacturing process, from raw material inspection to final product testing.

All incoming brass and copper materials are thoroughly tested for chemical composition, mechanical properties, and purity. During the stamping process, in – line inspections are carried out regularly to detect any potential defects early. After production, each part undergoes a series of tests, including electrical conductivity testing, dimensional inspection, and durability testing. We use advanced testing equipment and techniques to ensure accurate and reliable results. Any part that fails to meet our strict quality standards is rejected, and the root cause of the defect is investigated and addressed to prevent recurrence.

Future Prospects of Brass Copper Stamped Battery Button Contact Parts

Looking ahead, we are optimistic about the future prospects of our Brass Copper Stamped Battery Button Contact Parts. With the continuous growth of the electronics industry, the demand for high – quality battery contact parts is only expected to increase. As new technologies emerge, such as the development of more advanced battery chemistries and the miniaturization of electronic devices, there will be a greater need for precision – made contact parts.

We are committed to continuous research and development to stay ahead of the curve. Our team is constantly exploring new materials, manufacturing techniques, and design improvements to meet the evolving needs of our customers. By leveraging our expertise in brass and copper stamping, we aim to develop innovative solutions that not only meet but exceed industry standards, ensuring that our Brass Copper Stamped Battery Button Contact Parts remain a top choice in the global market for years to come.