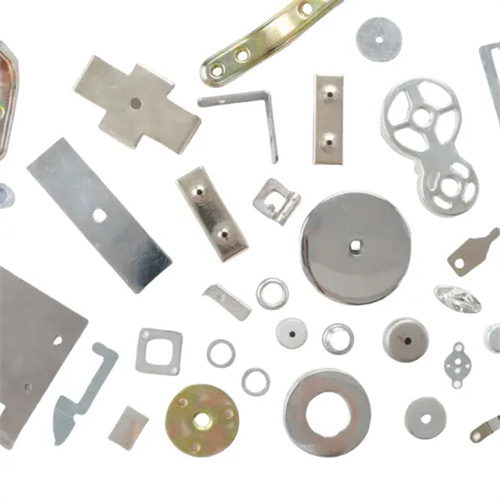

In the ever – evolving landscape of household appliances, precision stamped parts have emerged as indispensable components that significantly contribute to the functionality, durability, and efficiency of various home devices. These meticulously crafted parts, formed by precisely shaping metal sheets under high pressure, offer tailored solutions to meet the specific demands of different appliances. From enhancing the structural integrity of large – scale kitchen appliances to enabling the smooth operation of small – sized personal care devices, precision stamped parts play a crucial role in our pursuit of creating high – quality, reliable, and user – friendly home appliances. They have become an integral part of our manufacturing process, allowing us to deliver products that not only simplify daily life but also stand the test of time.

1. Precision Stamped Parts: Strengthening the Structure of Large – Scale Appliances

One of the primary applications of precision stamped parts in household appliances is in reinforcing the structure of large – scale devices such as refrigerators, washing machines, and ovens. We rely on precision – stamped metal frames and panels to provide a robust and stable foundation for these appliances. For instance, in refrigerators, precision – stamped steel frames are used to support the weight of the internal components, including the compressor, shelves, and drawers. These frames are stamped with exacting tolerances, ensuring a perfect fit for all parts and minimizing vibrations during operation. The stamping process allows for the creation of frames with integrated mounting points and channels for electrical wiring, streamlining the assembly process and enhancing the overall structural integrity of the refrigerator.

Similarly, in washing machines, precision – stamped metal tubs and outer casings are essential for withstanding the high – speed rotations and mechanical stresses during the wash cycle. The tubs, often stamped from durable stainless steel, are designed with smooth surfaces and precise dimensions to prevent entanglement and ensure efficient water circulation. The outer casings, stamped from high – strength steel or aluminum alloys, provide protection against external impacts and noise, creating a quiet and reliable operating environment for the appliance.

2. Precision Stamped Parts: Optimizing the Performance of Cooking Appliances

Precision stamped parts also play a vital role in optimizing the performance of cooking appliances such as stoves, microwaves, and toasters. In gas stoves, precision – stamped burner grates and control knobs are crucial for efficient heat distribution and user – friendly operation. The burner grates, typically stamped from cast iron or stainless steel, are designed with specific patterns and geometries to evenly spread the heat across the cookware, ensuring consistent cooking results. The control knobs, stamped with precise click – stop mechanisms, allow users to accurately adjust the flame intensity, providing precise control over the cooking process.

In microwave ovens, precision – stamped metal waveguides and shielding components are used to direct and contain the microwaves, ensuring efficient heating of the food while protecting users from radiation leakage. These parts are stamped with high precision to ensure proper alignment and seamless integration with other components. In toasters, precision – stamped metal heating elements and bread guides are designed to evenly toast the bread and prevent jamming. The heating elements, stamped from nickel – chromium alloys, are engineered to generate consistent heat, while the bread guides, stamped with smooth surfaces and precise dimensions, ensure that the bread slices are evenly toasted on both sides.

3. Precision Stamped Parts: Enhancing the Functionality of Small – Appliances

For small – sized household appliances like blenders, coffee makers, and hair dryers, precision stamped parts are essential for enhancing their functionality and user experience. In blenders, precision – stamped metal blades and drive shafts are key components for efficient blending. The blades, stamped from high – carbon steel and heat – treated for increased hardness, are designed with specific angles and cutting edges to effectively chop, blend, and puree various ingredients. The drive shafts, stamped with precise splines and diameters, ensure a secure connection between the motor and the blades, transmitting the power smoothly and reducing noise during operation.

In coffee makers, precision – stamped metal filters and valves are used to control the flow of water and coffee, ensuring a consistent and flavorful brew. The filters, stamped from stainless steel mesh with precise pore sizes, effectively trap coffee grounds while allowing the water to pass through. The valves, stamped with tight – fitting seals and accurate flow control mechanisms, regulate the water flow rate, ensuring that the coffee is brewed at the optimal temperature and extraction time. In hair dryers, precision – stamped metal heating elements and air vents are designed to generate and distribute heat evenly, providing fast and efficient drying while preventing overheating and damage to the hair.

4. Precision Stamped Parts: Ensuring Safety and Durability

Safety and durability are top priorities in the design of household appliances, and precision stamped parts contribute significantly to achieving these goals. We use precision – stamped metal components with rounded edges and smooth surfaces to prevent injuries during normal use. For example, in food processors, precision – stamped metal blades are designed with blunt tips and protective guards to minimize the risk of accidental cuts. The guards, stamped from durable plastic – coated metal, securely cover the blades when the appliance is not in use, ensuring user safety.

In addition, precision – stamped parts are engineered to withstand the rigors of daily use and maintain their performance over time. In vacuum cleaners, precision – stamped metal brush rolls and motor housings are designed to resist wear and tear from continuous contact with dust, dirt, and debris. The brush rolls, stamped from high – strength steel with durable bristles, effectively agitate and lift dirt from the floor, while the motor housings, stamped from heat – resistant alloys, protect the motor from overheating and damage, ensuring the long – term reliability of the vacuum cleaner.

5. Precision Stamped Parts: Driving Innovation in Home Appliance Design

As the home appliance industry continues to innovate, precision stamped parts are at the forefront of driving design advancements. Advanced stamping technologies, such as micro – stamping and 3D stamping, allow us to create parts with increasingly complex geometries and unique features. For example, in smart home appliances, precision – stamped metal components can be integrated with sensors and actuators, enabling functions such as automatic temperature control, remote monitoring, and voice activation. These parts are stamped with micro – scale features and precise holes for the installation of electronic components, ensuring seamless integration with the appliance’s control system.

The use of new materials in precision stamping, such as lightweight alloys and corrosion – resistant coatings, also opens up new possibilities for creating more energy – efficient and environmentally friendly home appliances. For instance, in energy – saving refrigerators, precision – stamped metal panels with insulated coatings can reduce heat transfer, minimizing energy consumption. By continuously exploring and applying new stamping technologies and materials, we can drive innovation in home appliance design, bringing forth products that are not only more functional and efficient but also more sustainable and aesthetically pleasing.