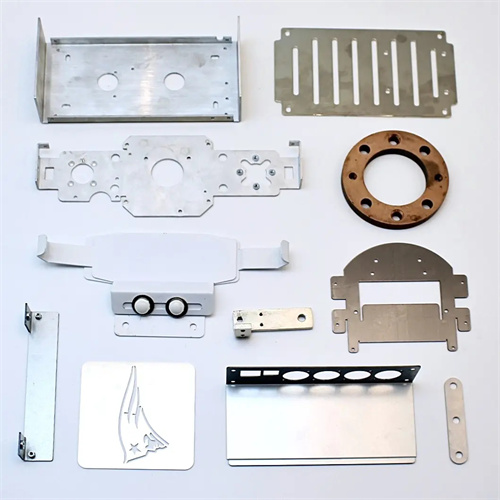

In the vibrant and imaginative world of the toy industry, custom stamped parts have emerged as indispensable components that breathe life into a wide array of playthings. These precisely crafted elements, shaped through the process of stamping metal sheets under high pressure, offer tailored solutions that enhance the functionality, durability, and aesthetic appeal of toys. From the simplest building blocks to the most complex interactive play sets, custom stamped parts play a crucial role in ensuring that toys not only entertain but also educate and inspire children. They have become an essential part of our toolkit, enabling us to create toys that meet the diverse needs and preferences of young minds while adhering to strict safety and quality standards.

1. Custom Stamped Parts: Building the Foundation of Toy Structures

In toy manufacturing, the structural integrity of a product is of utmost importance, and custom stamped parts serve as the foundation for many toys. When creating construction toys, such as metal building sets, we rely on custom – stamped metal beams, connectors, and plates. These parts are designed with precise dimensions and interlocking features, allowing children to assemble and disassemble the structures with ease. For instance, custom – stamped L – shaped connectors are engineered to fit snugly with the beams, providing a secure connection that can withstand the rough play of young builders. The stamping process ensures consistent quality, ensuring that each piece fits perfectly within the set, promoting creativity and problem – solving skills as children experiment with different designs. Moreover, in die – cast toy vehicles, custom – stamped metal frames provide the necessary strength and stability, enabling the toys to endure crashes and collisions during imaginative play scenarios.

2. Custom Stamped Parts: Enhancing Toy Functionality

Custom stamped parts also play a significant role in enhancing the functionality of toys. In action figures, custom – stamped metal joints allow for a wide range of motion, enabling children to pose the figures in various dynamic positions. These joints are stamped from durable metals, ensuring smooth movement while maintaining strength over time. For example, ball – and – socket joints, custom – stamped to fit the body parts of action figures, provide flexibility similar to human joints, allowing for realistic and creative play. In educational toys, such as mechanical learning kits, custom – stamped gears and cogs are essential components. These parts are stamped with precise tooth profiles to ensure proper meshing, teaching children about basic mechanical principles as they build and operate simple machines. The customizability of stamped parts means we can create gears of different sizes and ratios, offering endless possibilities for learning and exploration.

3. Custom Stamped Parts: Adding Aesthetic Appeal to Toys

Aesthetics are key in the toy industry, and custom stamped parts contribute significantly to making toys visually appealing. In collectible toys, custom – stamped metal emblems, badges, and decorative plates add a touch of authenticity and charm. These parts can be stamped with intricate designs, logos, or patterns, making each toy unique and highly desirable for collectors. For example, in limited – edition toy cars, custom – stamped metal emblems on the hood or fenders showcase the brand’s logo in high – detail, enhancing the overall value and allure of the product. Additionally, custom – stamped metal trim pieces on dolls’ clothing or toy furniture can elevate the appearance, giving the toys a more realistic and sophisticated look. The ability to customize the finish of stamped parts, such as applying different coatings or platings, allows us to create toys that stand out on store shelves and capture the attention of children and parents alike.

4. Custom Stamped Parts: Ensuring Toy Safety

Safety is the top priority in toy production, and custom stamped parts are designed with this in mind. We use non – toxic and child – safe metals in the stamping process to ensure that toys pose no health risks to children. Rigorous quality control measures are applied to custom – stamped parts to eliminate sharp edges or rough surfaces that could cause injuries. For example, in toy trains, custom – stamped metal wheels are carefully inspected to ensure smooth edges and proper alignment, preventing any potential harm during play. Moreover, custom – stamped parts are often designed with safety features, such as locking mechanisms in toy storage boxes or secure fasteners in playsets. These features are engineered to withstand the forceful handling of children, ensuring that the toys remain intact and safe during use. By adhering to strict safety standards in the production of custom stamped parts, we can provide parents with peace of mind knowing that the toys their children play with are reliable and secure.

5. Custom Stamped Parts: Driving Innovation in Toy Design

As the toy industry continues to evolve, custom stamped parts are at the forefront of driving innovation in toy design. Advanced stamping technologies, such as micro – stamping and 3D stamping, allow us to create parts with increasingly complex geometries and features. This enables the development of innovative toys that incorporate advanced functions and interactivity. For instance, in smart toys, custom – stamped metal components can be used to create conductive pathways for electronic circuits, enabling features like touch – sensitive responses or wireless connectivity. The use of new materials in custom stamping, such as lightweight alloys and biodegradable metals, also opens up new possibilities for sustainable toy design. We can now create eco – friendly toys that not only meet the demands of environmentally – conscious consumers but also reduce the industry’s environmental impact. Custom stamped parts thus continue to be a catalyst for creativity and progress in the toy industry, shaping the future of play.