In the dynamic and highly competitive realm of sports, where every detail can make a difference between victory and defeat, custom stamped parts have become indispensable components in the creation of top – tier sports goods. These precision – engineered elements, shaped through the meticulous process of stamping metal sheets under high pressure, offer tailored solutions that enhance the performance, safety, durability, and functionality of a wide range of sports equipment. From professional athletes seeking a competitive edge to casual sports enthusiasts enjoying their favorite activities, custom stamped parts play a crucial role in ensuring that sports gear meets the diverse and exacting demands of modern sports.

1. Custom Stamped Parts: Unleashing Peak Athletic Performance

Custom stamped parts are at the heart of many innovations aimed at elevating athletic performance. In the cycling world, we leverage custom – stamped components to craft frames that are a perfect blend of lightweight design and exceptional strength. For instance, high – end road bikes often feature frames made from custom – stamped aluminum alloys. Through advanced stamping techniques, we can shape the metal into complex aerodynamic profiles, reducing air resistance and allowing cyclists to achieve higher speeds with less effort. The precision of stamping ensures that each tube and joint fits perfectly, creating a rigid structure that efficiently transfers the rider’s power to the pedals. In track and field, custom – stamped spikes are carefully designed to optimize traction on different surfaces. For running on synthetic tracks, we stamp spikes from hard – wearing metals with a specific number of pins and lengths to provide maximum grip without adding excessive weight. This enables sprinters to accelerate quickly and maintain stability during explosive starts and high – speed runs.

2. Custom Stamped Parts: Fortifying Protective Sports Equipment

Safety is non – negotiable in sports, and custom stamped parts are key to developing effective protective gear. In football, custom – stamped metal plates are integrated into helmets, shoulder pads, and thigh guards. These plates, typically made from high – strength steel or lightweight titanium alloys, are stamped to precise specifications to offer superior impact resistance. The face masks on football helmets, for example, are custom – stamped to provide a balance between protection and visibility. The intricate stamping process allows for the creation of a lattice – like structure that can withstand powerful blows from opponents while still enabling players to see clearly on the field. In ice hockey, custom – stamped steel cages on helmets and metal – reinforced shin guards protect players from high – velocity pucks and rough physical contact. The stamping process also allows for the customization of these protective elements to fit different body shapes and sizes, ensuring a snug and secure fit that maximizes safety.

3. Custom Stamped Parts: Ensuring Long – lasting Equipment Durability

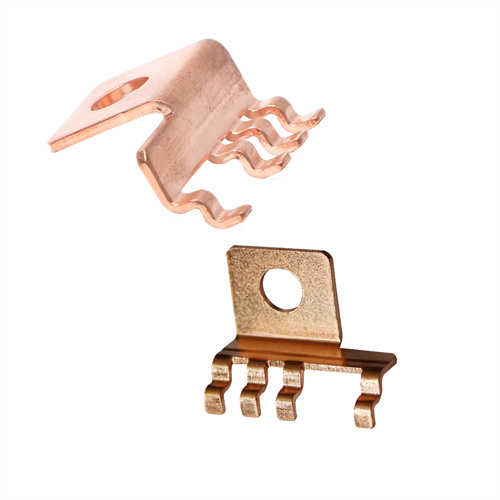

The durability of sports equipment is essential, given the intense and repetitive use it endures. Custom stamped parts significantly contribute to extending the lifespan of sports goods. In tennis, custom – stamped metal grommets are inserted into the racket frame to protect the strings. These grommets are stamped from corrosion – resistant metals and designed with precise inner diameters to ensure a smooth passage for the strings. By evenly distributing the tension, they prevent the strings from rubbing against the frame and breaking prematurely. In baseball bats, custom – stamped end caps made from durable alloys are attached to the bottom of the bat. These end caps, shaped through stamping, help balance the bat and protect it from damage during impacts with the ground or dugout walls. Additionally, in fitness equipment like weightlifting machines, custom – stamped metal brackets and connectors are used to reinforce the structure. These parts are stamped to withstand heavy loads and constant movement, ensuring the safety and reliability of the equipment over long – term use.

4. Custom Stamped Parts: Enhancing Recreational Sports Gear

Custom stamped parts are not limited to professional sports; they also enhance the functionality and user experience of recreational sports gear. In outdoor activities such as camping and hiking, custom – stamped metal buckles and clips are used to secure backpacks, tents, and other equipment. These parts are stamped from corrosion – resistant stainless steel or lightweight aluminum alloys, ensuring they can withstand harsh outdoor conditions. The stamping process allows for the creation of ergonomic designs that are easy to operate, even with gloved hands. In water sports like kayaking and paddleboarding, custom – stamped metal fittings are used to attach seats, footrests, and accessories. These fittings are designed to be resistant to saltwater corrosion and are stamped with precise holes and grooves for a secure and leak – free connection. For example, custom – stamped metal brackets on a kayak can be adjusted to fit different paddlers’ leg lengths, providing a comfortable and efficient paddling experience.

5. Custom Stamped Parts: Driving Innovation in Sports Equipment Design

As the sports industry continues to evolve, custom stamped parts are at the forefront of driving innovation in sports equipment design. Advanced stamping technologies, such as computer – controlled progressive stamping and 3D stamping, enable us to create parts with complex geometries and unique features. In the design of swimwear, custom – stamped metal rings and clasps are used to create more form – fitting and hydrodynamic designs. These parts can be stamped with intricate patterns and textures that not only enhance the aesthetic appeal but also reduce drag in the water. In the emerging field of e – sports, custom – stamped metal components are used in gaming chairs to provide adjustable and sturdy support. The stamping process allows for the integration of features like reclining mechanisms and height – adjustable legs, ensuring comfort during long gaming sessions. Moreover, the exploration of new materials in custom stamping, such as carbon – fiber – reinforced polymers and shape – memory alloys, opens up exciting possibilities for developing sports equipment that is lighter, stronger, and more intelligent, revolutionizing the way we play and experience sports.