In the intricate and highly regulated realm of medical devices, custom stamped parts have emerged as indispensable elements that underpin the functionality, safety, and innovation of healthcare equipment. These precisely crafted components, formed by shaping metal sheets under high pressure, offer tailored solutions to meet the stringent demands of medical applications. From life – saving surgical tools to advanced diagnostic equipment, custom stamped parts play a pivotal role in ensuring that medical devices deliver accurate results, enhance patient care, and adhere to the highest standards of quality. They have become an essential part of our manufacturing arsenal, enabling us to create cutting – edge medical solutions that drive the progress of modern healthcare.

1. Custom Stamped Parts: Precision – Engineered Surgical Instruments

Custom stamped parts are the backbone of precision – engineered surgical instruments. When crafting scalpels, we rely on custom – stamped blades made from high – grade stainless steel or titanium alloys. These blades are stamped to exacting tolerances, resulting in an ultra – sharp and consistent edge that is crucial for making clean incisions during delicate surgeries. The stamping process allows for the creation of complex blade shapes, such as the curved blades used in ophthalmic procedures, which require intricate geometries to access hard – to – reach areas with precision.

In forceps and clamps, custom – stamped metal components form the handles and jaws. The jaws are stamped with specific patterns and serrations to provide a secure grip on tissues without causing unnecessary damage. The pivot points, custom – stamped with high accuracy, ensure smooth and controlled movement, enabling surgeons to perform operations with dexterity and confidence. For example, in laparoscopic surgeries, custom – stamped components in specialized forceps allow for precise manipulation within the limited space of the abdominal cavity, minimizing trauma to surrounding tissues.

2. Custom Stamped Parts: Enhancing Diagnostic Equipment Performance

For diagnostic equipment, custom stamped parts play a vital role in ensuring accurate and reliable results. In X – ray machines, custom – stamped metal shielding components are essential for protecting patients and medical staff from harmful radiation. These shielding parts are typically stamped from lead – lined or lead – equivalent materials and are designed to fit snugly around the X – ray tube and other radiation – emitting components. The stamping process enables the creation of complex shapes that conform to the intricate designs of the equipment, providing maximum protection while minimizing interference with the imaging process.

In ultrasound devices, custom – stamped metal housings safeguard the delicate internal components and ensure proper acoustic coupling. These housings are stamped with precisely positioned holes and openings for the transducer elements, allowing for optimal transmission and reception of ultrasonic waves. This precision is crucial for obtaining clear and detailed images of internal body structures, enabling accurate diagnosis. Additionally, in magnetic resonance imaging (MRI) machines, custom – stamped metal parts are used to create components that are compatible with the strong magnetic fields, ensuring the smooth operation of the equipment.

3. Custom Stamped Parts: Ensuring Patient Safety and Comfort

Patient safety and comfort are paramount in medical device design, and custom stamped parts contribute significantly to achieving these goals. In infusion pumps, custom – stamped metal brackets and connectors securely hold the tubing in place. These parts are designed with smooth surfaces and rounded edges to prevent any damage to the tubing, ensuring a continuous and accurate flow of medications. The custom – stamped components also facilitate easy installation and removal of the tubing, reducing the risk of contamination and improving the efficiency of healthcare providers.

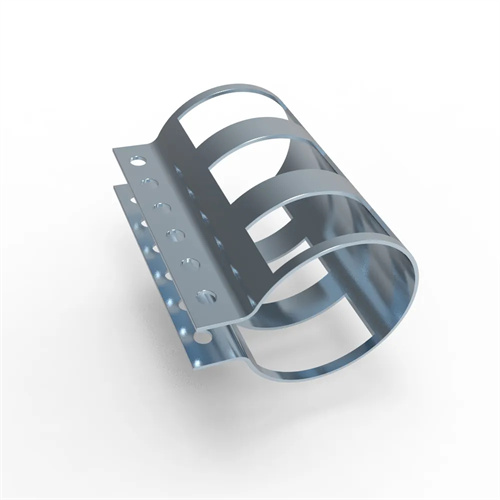

In hospital beds and wheelchairs, custom – stamped metal frames provide the necessary strength and stability while maintaining a lightweight design. The frames are stamped with precision – engineered holes and slots for attaching various accessories, such as adjustable armrests, footrests, and side rails. This customization allows for the accommodation of individual patient needs, enhancing their comfort and mobility. Moreover, the corrosion – resistant properties of the stamped metal parts ensure the longevity of the equipment, even in the demanding hospital environment.

4. Custom Stamped Parts: Enabling Minimally Invasive Procedures

With the increasing popularity of minimally invasive procedures, custom stamped parts have become essential in the development of specialized medical devices. In endoscopic instruments, custom – stamped metal components are used to create the slender and flexible shafts that can navigate through the body’s natural orifices and cavities. These components are stamped from high – strength, corrosion – resistant alloys and are designed to withstand the rigors of repeated use.

The stamping process allows for the integration of features such as channels for irrigation, suction, and the passage of surgical tools. For example, in endovascular procedures, custom – stamped metal catheters with precisely shaped tips and lumens enable the delivery of treatments to targeted areas within blood vessels. Additionally, in robotic surgical systems, custom – stamped metal joints and connectors provide the flexibility and precision required for the robotic arms to perform complex maneuvers with enhanced dexterity, reducing the invasiveness of surgeries and improving patient outcomes.

5. Custom Stamped Parts: Pioneering Innovation in Medical Device Manufacturing

As the medical device industry continues to evolve, custom stamped parts are at the forefront of driving innovation. Advanced stamping technologies, such as micro – stamping and 3D stamping, allow us to create parts with increasingly complex geometries and micro – scale features. In the development of lab – on – a – chip devices, custom – stamped microfluidic components with intricate channel networks enable the miniaturization of diagnostic and analytical processes. These components can perform multiple functions, such as sample handling, mixing, and detection, in a compact and efficient manner.

The use of new materials in custom stamping, such as biocompatible alloys and shape – memory metals, opens up new possibilities for implantable medical devices. Custom – stamped parts can be designed to integrate sensors and actuators, enabling real – time monitoring and control of physiological parameters. For instance, in smart implants, custom – stamped metal components can house micro – sensors that continuously measure parameters like blood pressure or glucose levels and transmit the data wirelessly. These innovations in custom stamping not only improve the performance and functionality of medical devices but also have the potential to transform patient care and treatment paradigms.