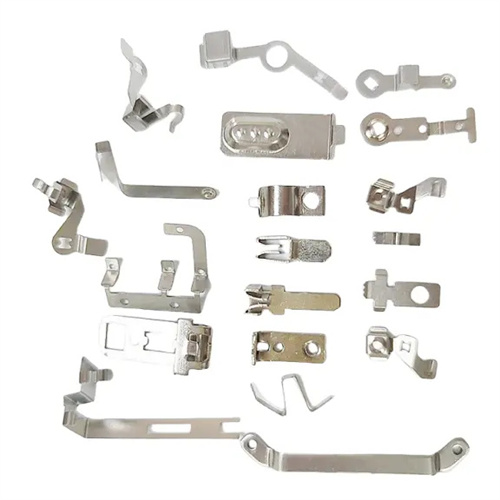

Spring Steel Stamped Parts

In our factory’s production practice, spring steel stamped parts stand out with excellent elasticity and high strength performance. By using a special alloy formula and heat treatment process, spring steel stamped parts can quickly recover to their original state after repeated deformation, with excellent fatigue resistance and the ability to withstand over a million cyclic loads without failure. At the same time, its high-strength characteristics enable the parts to maintain a stable structure under complex working conditions, with a maximum tensile strength of over 1800MPa, meeting the requirements of high stress environments. Our factory relies on high-precision stamping equipment and independently developed mold technology to punch spring steel into various complex shapes with dimensional accuracy controlled within ± 0.02mm, ensuring product consistency. In addition, spring steel stamped parts also have good wear resistance, which can effectively extend their service life and reduce customer maintenance costs.

Material selection for Spring Steel Stamped Parts

Our factory reserves a variety of high-quality spring steel materials to meet the performance requirements of different products. Commonly used is 65Mn spring steel, which has moderate cost and good hardenability, and is suitable for manufacturing springs and elastic components that meet general requirements; 55Si2Mn spring steel contains alloy elements such as silicon and manganese, which have high elastic limit and fatigue strength. It is commonly used to make automotive leaf springs, coil springs, etc. that can withstand large loads; For parts that need to maintain elasticity in high temperature environments, 50CrVA spring steel is selected, which has good high-temperature strength and oxidation resistance. In addition, our factory can also purchase imported spring steel materials or customize spring steel with special alloy compositions according to customers’ special requirements, providing quality assurance for products from the source.

Spring Steel Stamped Parts Production Process

Spring steel stamped parts follow strict and scientific production processes in our factory. Firstly, according to the product design requirements, use appropriate sized blanks. Subsequently, the billet enters the stamping process and is formed on high-speed stamping equipment using multi station progressive dies or precision single process dies. By precisely controlling the stamping pressure, speed, and stroke, the shape and dimensional accuracy of the parts are ensured. After stamping, the parts need to undergo key heat treatment processes, including quenching, tempering, etc., to optimize the material’s microstructure, improve elasticity and strength performance. After heat treatment, the surface of the parts is cleaned to remove impurities such as oxide scale, and then the size, hardness, elasticity, and other indicators of the parts are comprehensively tested through automated testing equipment. Finally, rust proof packaging should be carried out according to customer requirements to ensure that the product is not damaged during transportation and storage.

Surface treatment of Spring Steel Stamped Parts

To further improve the performance and service life of spring steel stamped parts, our factory provides diversified surface treatment processes. In terms of electroplating treatment, operations such as galvanizing, nickel plating, and cadmium plating can be carried out to effectively enhance the anti-corrosion ability of parts, especially suitable for environments with humid or corrosive media; For products that require higher levels of protection, Dacromet coating treatment is used, which has excellent salt spray corrosion resistance and no risk of hydrogen embrittlement; In addition, a protective film can be formed on the surface of the parts through phosphating treatment to improve wear resistance and lubricity, and reduce friction losses. If customers have special requirements for appearance, our factory can also provide surface treatment methods such as painting and electrophoresis to give personalized color and texture to the product.

Application of Spring Steel Stamped Parts products

The spring steel stamped parts produced by our factory are widely used in multiple industries due to their excellent performance. In the field of automobile manufacturing, it is used to manufacture key components such as engine valve springs, clutch springs, suspension springs, etc., to ensure the stable operation of automobile power systems and driving systems; In the electronic device industry, we produce mobile phone vibration springs, elastic contact pieces for precision instruments, etc., to meet the requirements of miniaturization and high reliability for electronic products; In the medical device industry, springs used in cardiac stent delivery systems and elastic components of surgical instruments provide support for precise operation of medical equipment; In addition, spring steel stamped parts also play an important role in the fields of mechanical manufacturing, aerospace, furniture hardware, etc., such as the mainspring of mechanical clocks, the shock absorber spring of airplane seats, the hinge spring of furniture, etc., winning the trust of many customers with reliable performance.