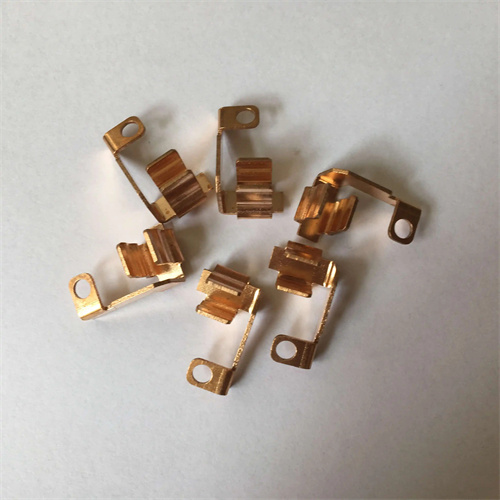

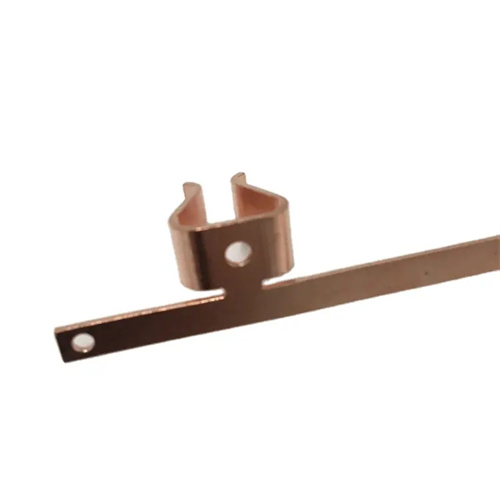

Brass Copper Stamped Parts

Brass and copper stamped parts exhibit significant advantages. Its excellent conductivity and thermal conductivity make it an ideal choice in the field of electronic appliances, ensuring efficient transmission of current and heat; Good corrosion resistance enables the product to maintain stable performance even in harsh environments, greatly reducing customer maintenance costs. With advanced stamping equipment and mature processes, we can punch brass and copper into complex shaped parts with an accuracy of ± 0.01mm, meeting high-precision requirements. At the same time, the ductility and plasticity of the material itself result in high surface smoothness of the parts, reducing subsequent processing steps and saving customers time and costs.

Material selection for Brass Copper Stamped Parts

We reserve a variety of brass and copper materials to meet different product needs. Common brass models include H62, H65, H70, etc. H62 brass has high strength and moderate price, making it suitable for general parts with high mechanical performance requirements; H70 brass has good plasticity and strong corrosion resistance, and is commonly used in the manufacturing of precision parts that require deep drawing processing. Pure copper (purple copper) is commonly used in the production of electronic components, conductive terminals, etc. due to its high purity and excellent conductivity. In addition, we can also purchase special alloy copper materials such as phosphor bronze, beryllium bronze, etc. according to customers’ special requirements. Through customized material selection, we can provide customers with products that better meet their needs.

Production process of Brass Copper Stamped Parts

Our factory has established a standardized and efficient production process for brass and copper stamped parts. Firstly, according to the customer’s drawings and requirements, use a high-precision laser cutting machine to cut brass or copper plate materials into suitable sizes. Next, with advanced CNC stamping equipment and high-precision molds, the stamping of the parts is completed under strict pressure and speed parameter control, resulting in high production efficiency and good consistency. The formed parts will enter the automated deburring equipment to remove excess corners and burrs, ensuring a smooth surface. Subsequently, precision testing equipment such as coordinate measuring instruments and image measuring instruments were used to conduct comprehensive inspections of the size, shape, and performance of the parts, ensuring that the product quality meets the standards. Finally, packaging should be carried out according to customer requirements, using anti-static and moisture-proof packaging materials to ensure the safety of the product during transportation and storage.

Brass Copper Stamped Parts Surface Treatment

To enhance product performance and appearance, our factory is equipped with a comprehensive surface treatment production line. In terms of electroplating, nickel plating, chrome plating, gold plating and other treatments can be carried out to enhance the corrosion resistance and aesthetics of the parts, meeting different decorative and functional needs. Chemical oxidation treatment can form a dense oxide film on the surface of parts, improving their oxidation and corrosion resistance. For products that require high surface smoothness, we use processes such as mechanical polishing and electrolytic polishing to achieve a mirror like effect on the surface of the parts. In addition, we also provide surface treatment services such as spray painting and electrophoresis, which enable our products to better adapt to different usage environments and customer needs through diverse treatment methods.

Application of Brass Copper Stamped Parts products

With high-quality and diversified products, our brass and copper stamping parts are widely used in multiple industries. In the field of electronic communication, we produce various precision connectors, connectors, terminals, etc. for customers to ensure stable signal transmission; In the automotive manufacturing industry, we supply automotive wiring harness terminals, heat sinks, conductive connectors, etc. to assist in the efficient operation of automotive electrical systems. In the hardware and bathroom industry, manufacturing faucet accessories, decorative handles, etc. is favored by customers for its good corrosion resistance and aesthetics. At the same time, in high-end fields such as aerospace and medical equipment, we also provide customized brass and copper stamping products for customers, meeting the strict requirements of the industry with high precision and reliable performance.